- A lot of future megatrends are already reflected today at NürnbergMesse trade fairs and congresses

- Sustainability: clean tech ensures the responsible use of resources

- Internet of Things: solutions for the interconnected world of tomorrow

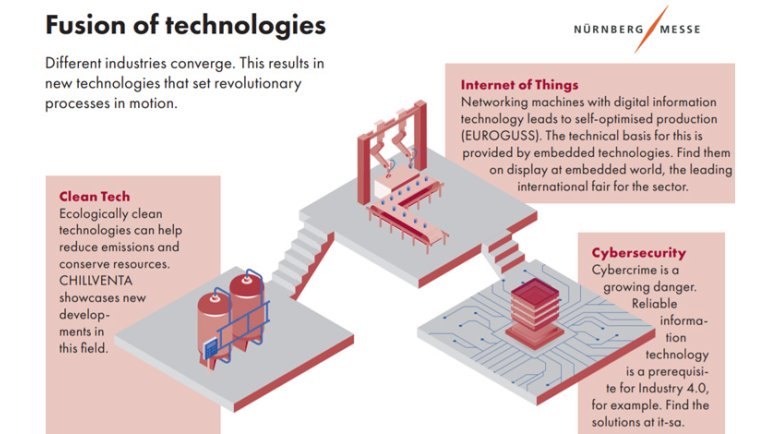

The megatrends digitalisation, Industry 4.0, the Internet of Things and the call for resource-conserving technologies are having a huge impact on the day-to-day business of many companies. Researchers currently assume that one megatrend in particular will be very important in the future: technology convergence. Specifically, this brings together different industry sectors that would have operated completely separately from one another in the past. Together they create considerable synergies through innovative technologies and as a result also ensure new markets. “At our trade fairs and congresses, companies are showing in an impressive way how technologies are converging with one another and the ideas and products that result,” explains Peter Ottmann, CEO of NürnbergMesse Group. “The advantage for companies in particular is that our events enable these megatrends to be made tangible,” says his fellow CEO Dr Roland Fleck about this conceptual approach. “Our high-tech fairs in particular are a hot spot for the latest trends and for tomorrow’s products and innovations.”

It’s one thing to track down trends, but the far greater challenge is to convert them into successful trade fair concepts. However, for Peter Ottmann, that’s precisely when the whole process gets so interesting: “After all, the litmus test has not been passed until the trade fair concept is in tune with the market. Our customers are genuine yardsticks for the acceptance of an event. And for them, the effective representation of trends is often one of the criteria for success.”

The UN Climate Change Conference in Madrid has again made clear that growing ecological awareness, the economic pursuit of efficiency improvements and the will to permanently reduce CO² necessitate clean technologies and processes that are sustainable. Clean tech is being put into practice at more and more companies. Its objective is to completely avoid emissions while taking account of economic aspects. For example, numerous companies are using the waste heat from the manufacture of their products to recover energy. This cuts their total energy footprint considerably and avoids unnecessary emissions. “In 2020 Chillventa – the exhibition for energy efficiency, heat pumps and refrigeration, will take an in-depth look at the ‘overall energy performance’ of equipment and systems. What is meant by that? For many decades, the individual components of the refrigeration cycle were the centre of attention. Innovations and refinements, and at Chillventa in particular the energy efficiency (EE) of components, continue to be the focus,” says Dr Rainer M. Jakobs from DMJ Consulting. “The ‘don’t waste heat’ trend means that the increased use of the waste heat from refrigeration systems, or even better the simultaneous use of the cold and warm sides of the system, along with combined heat, power and cooling, are being given top priority and becoming genuine ‘clean technologies’. The efficiency of these kinds of systems is influenced by the individual components but to a much greater degree by an overall optimisation and evaluation of the system benefits. To this end the overall energy performance needs to be defined in order to then better evaluate the systems,” explains Jakobs.

In addition, digitalisation and the Internet of Things (IoT) are playing an increasingly important role, especially in the processing industry, where the interconnection of machines or processes with digital information and communication technologies can make production much more efficient. Embedded technologies form the technical basis for interconnected systems – to be seen at the world's leading trade fair embedded world, which takes place from 25 to 27 February 2020. Among other things, the focus will be on condition monitoring and the predictive maintenance of machines, systems or system components based on this. How the interconnection of machines or processes is implemented in practice will be demonstrated at EUROGUSS, the International Trade Fair for Die Casting in Nuremberg (14-16 January 2020).

At Bühler AG, for example, the focus is on production with fewer breakdowns, which saves costs and resources. Its Director of Product Management & Marketing, Marcello Fabbroni, had this to say: “To bring productivity in die casting to a new level, the factors that we need to work on are rejects, cycle time and availability. The first step in this direction is to use digital technologies not just in the casting machine but to monitor, control and manage the entire die casting cell from a central location.”

Interconnectedness and real-time monitoring offer other advantages for the die casting industry. IFAM, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials, has developed a method for integrating RFID (radio frequency identification) transponders into cast metal parts. This allows electronic radio-frequency identification and recognition of cast products. “The RFID transponder can be mounted retrospectively to existing cast parts or embedded into the part during the casting process as such,” says Franz-Josef Wöstmann, Head of the Foundry Technology and Lightweight Design Department at the Fraunhofer IFAM. “The RFID transponder has a globally unique serial number and can be expanded to include customized code numbers. The benefits over previous marking methods like barcodes are obvious: an unambiguous, un-detachable marking that is resistant to environmental influences is guaranteed. This protects the parts from counterfeiting, allows them to be traced over the entire supply chain and also generates new business models.”

“Digitalisation and the Internet of Things are without doubt the latest megatrends and no company can afford to neglect these areas. At the same time there are more and more reports about hacker attacks paralysing websites, equipment and entire companies,” says Dr Christian Ellwein, Managing Director of KRIWAN Industrie-Elektronik GmbH. “To tackle the digitalisation process successfully and securely it is extremely important that from the very outset, cyber security is handled as a matter for top management as well. This is the only way to also ensure the security of the digitalisation process. Interconnected devices and machines communicate using wireless connections, which makes them vulnerable to cyber-criminality. Companies are therefore asking themselves how they can protect themselves from hacker attacks and safeguard interconnected devices against data theft. Reliable information technology is therefore a necessary prerequisite for Industry 4.0. The resulting challenge is to establish systems that manage to preserve confidentiality and at the same time avoid production downtimes. At it-sa, the IT security trade fair and congress, industry experts came together to find out about the latest developments and trends. From 8-10 October 2019, the world’s largest IT security fair attracted 756 exhibitors and almost 15,600 German and international trade visitors to Exhibition Centre Nuremberg.

Whether they take part in it-sa, EUROGUSS, embedded world or Chillventa, more and more exhibitors are choosing NürnbergMesse events to get comprehensive information about megatrends and present their own interpretation of them. For Dr Roland Fleck, this is an important insight, because it makes clear: “Megatrends like digitalisation or the ‘convergence of technologies’ strengthen our international trade fairs, because this is where you can get hands-on with the products and experience the interconnectedness of the machines in a way that also results in new contacts and business opportunities.”